Kingland Eyeware

One of the most common disconnects I’ve seen between design and manufacturing lies in the specifics of material finishes. As a designer, it’s easy to imagine a perfect finish and push to achieve that vision, often without fully understanding the steps, costs, and compromises required to realize it. But I’ve learned that some of the most beautiful finishes are not the ones we impose, but the ones that emerge naturally from the production process itself.

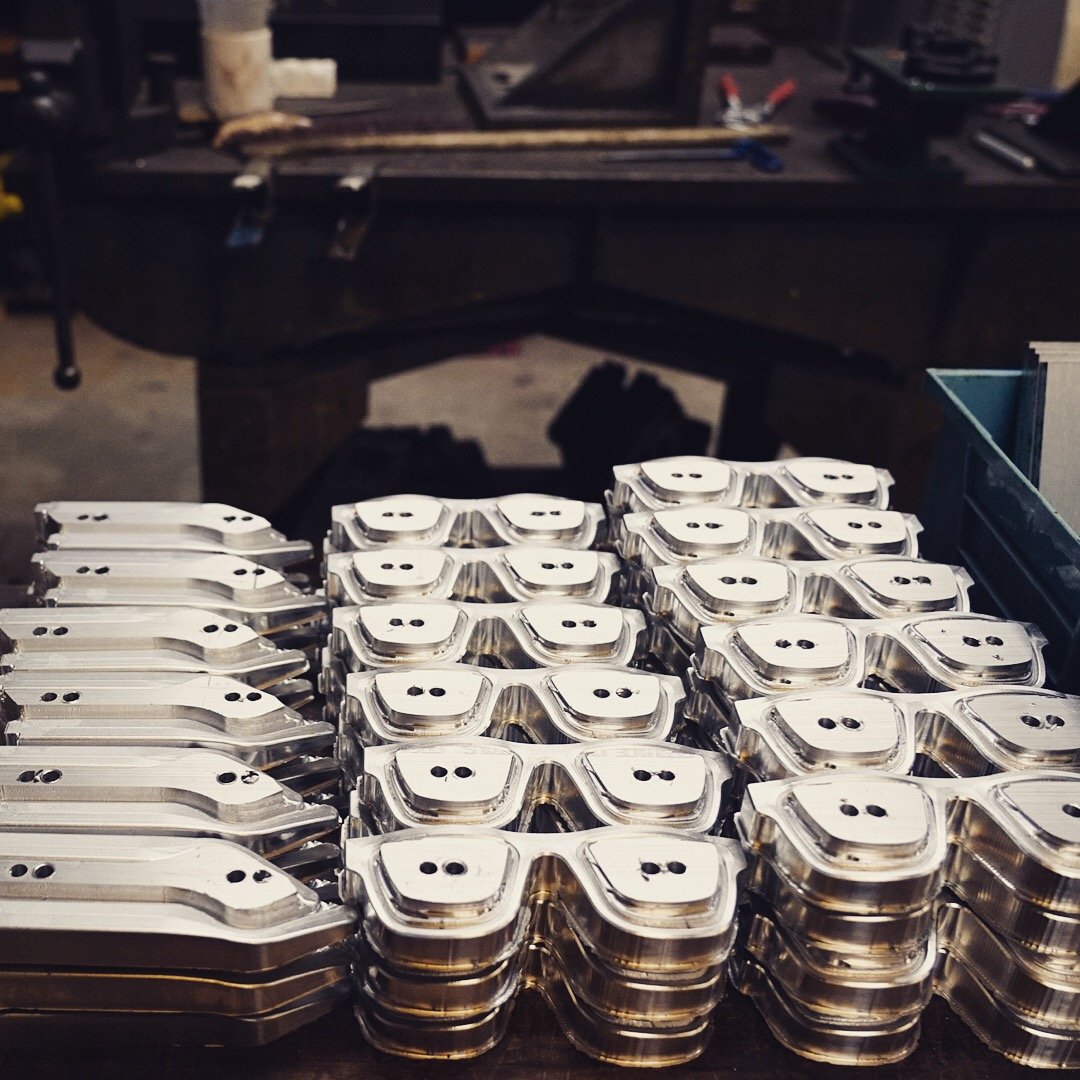

These inherent qualities, whether a machining pattern, a casting texture, or the raw tone of an untreated surface, can be more honest, expressive, and beautiful than a layer of paint or polish. Recognizing and celebrating these finishes requires active collaboration. I make it a point to engage closely with manufacturing teams early in the process, listening carefully to their insights and constraints. Often, they reveal material behaviors or process characteristics that can shape the final design in a way that feels both intentional and effortless.

By inviting production realities into the design process, rather than resisting them, I’ve found we can create products that are not only manufacturable but deeply rooted in the beauty of how they’re made.

The lines you see are the natural paths of the CNC milling machine that cut the frames.